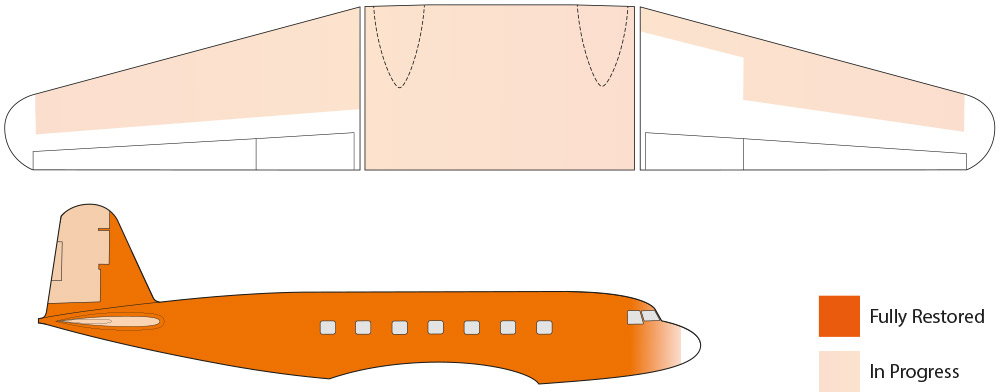

Restoration Progress

Areas of the DC-2 currently being worked on.

Our program for 2026

- Continue rebuilding the main wing centre section in preparation for mating with the fuselage.

- Rebuild the port engine nacelle.

- Complete the rebuild of our spare engine to running condition for public demonstrations.

- Begin restoration of the wing centre section trailing edge assembly.

- Restore and fit cargo door to fuselage.

Completed in 2025

- Mating of the rebuilt centre section leading edge assembly to the main wing centre section.

- Rebuilding of the starboard engine nacelle.

- Installation of new museum display area

- Installation of exterior cockpit door

The wing centre section taking shape.

Completed in 2024

- Navigators compartment

- Cockpit area

- Skinning the forward section of fuselage

- Front baggage door and door frame

- Complete stripping of the wing centre section

- Beginning to rebuild of wing centre section, expected to take up to 18 months

- Work started on rebuilding our spare engine. We hope to be able to have this engine running in the future.

Completed in 2023

- Rear baggage bulkhead

- Cargo door frame

- Main cabin fully restored and rebuilt

- Main floor frames

- Front cabin bulk head

- Continued disassembly of the wing centre section

- Completed our spray booth and skin restoration area

An example of severe corrosion in the DC-2

The same part of the aircraft completely restored.

Fully restored rear bulkhead at the rear of the fuselage.

Completed in 2022

- Rebuilt and fitted the fin extension

- 90% of the work from the baggage compartment through to the main cabin area

- Rebuilt and fitted the tail cone

- Removed the jig from the fuselage to give better access to the outer fuselage

- Partial removal of skins from port and starboard wings to inspect for corrosion damage

- Partial removal of skins of centre wing section

Completed in 2021

- Tail section restoration continued and we began riveting skins in place

- Fin completed and test fitted to the fuselage

- The rudder although not completely finished was moved into place for trial fit

- We began removing lower surface skins and mounting blocks of wing centre section, to inspect for corrosion damage

- Landing gear was completed ready for final coat of paint

- A new rotating engine overhaul mount was built

- New outer wing stands were fabricated and installed

- Started removing upper cabin skins and replacing corroded stringers

Overview of activities in 2020

- In January 2020 the UMCT took possession of a newer, far more spacious hangar at 7 Bristol Court, Albury Airport. The aircraft was relocated to the new hangar in January and restoration work proceeded

- Cleaning 10 years accumulated dirt and bird dropping from the roof trusses and floor

- Offices and crew room repainted

- Built the security fence to make the building secure

- Moved parts and equipment from our old hangar (an enormous job)

- Painted the floor in the work area

- Built the overhead structure to carry air and power to each work area and moved machinery into place

- COVID-19 struck and we were forced to suspend the work of most volunteers for several months. During this time we were able to build benches, stands, work platforms

- Work recommenced and we were able to experiment and develop new work practices and procedures to help refine and speed up the restoration process

- Progress made with polishing, paint stripping or buffing out extensive corrosion

- Manufacture of many new parts.

Thank-you to our tireless volunteers!

At the beginning of the restoration process the DC-2 had been sitting out in the open air for 37 years and had become badly weathered and corroded.

Disassembly of the DC-2s outer wings, tail fin, engines and propellors began in January 2016 with a small band of enthusiastic volunteers. This was conducted on the open grass area beside the “Pickles” hangar, where Council had left it.

The wings, engines, propellors, tailplane, and fin were gradually removed and relocated to the Smartair hangar, and a Pickles crane towed the whole fuselage into the hangar on 12 May 2016.

A call went out for volunteers in the Albury-Wodonga region and on 14 May 2016, 30 people underwent our first volunteer induction training. A year later, at least 50 people had done the induction.

We have men and women from a wide range of ages who come to the regular work days (Wednesdays and Saturdays).

Early tasks included removing aluminium cladding on the ailerons (nonstandard), disassembling the propellors, wheel hubs, and tailwheel structure, beadblasting corroded parts, making workbenches, and many other tasks.

In the first half of 2017, the fuselage and centre-wing were de-mated, the engine nacelles were removed from the centre-wing, the tailwheel and main undercarriage was all removed, and the inner lining of the fuselage was removed. In other words, all the major assemblies were separated.

Later in 2017 we began repair of the rudder, cleaning and jigging of the engine nacelles, disassembly of the horizontal stabilisers, further disassembly and repair to the undercarriage, straightening the bent engine mount, tool-making, and prepared to send the propellers to Melbourne for specialised repairs.

This community project is powered by donations and volunteers. Please consider making a donation.

© Copyright Uiver Memorial Community Trust 2012-2026

Hosting kindly donated by Coxtech